Japan Testing, Inspection & Certification Market: By Service Type (Testing Services, Inspection Services, Certification Services, Training, Consultancy); Solution Type (In-house Services and Outsource Services); Application (Quality and Safety, Production Evaluation, Industrial Inspection, System Certification, Others); End User (Consumer Goods & Retail, Food & Agriculture, Oil & Gas, Construction & Engineering, Water and Wastewater, Education, Energy & Chemistry, Industrial Product Manufacturing, Transportation (Rail & Aerospace) and Tourism, Automotive, Other)—Market Size, Industry Dynamics, Opportunity Analysis and Forecast for 2025–2033

- Last Updated: 05-Jul-2025 | | Report ID: AA07251367

Market Scenario

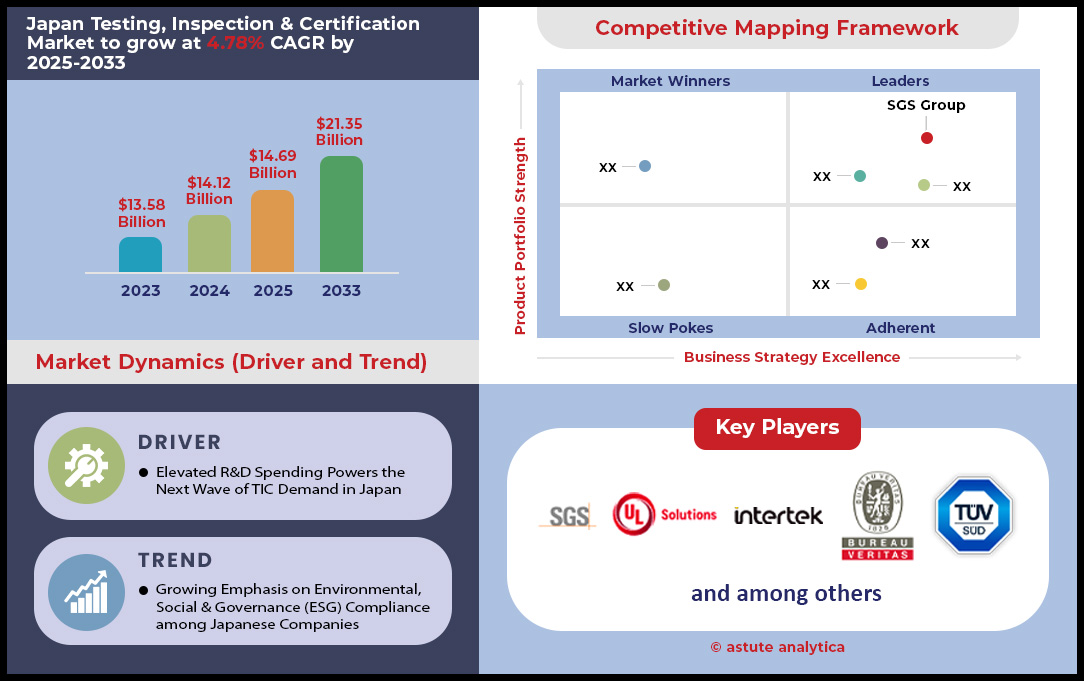

Japan testing, inspection & certification market was valued at US$ 14.12 billion in 2024 and is projected to hit the market valuation of US$ 21.35 billion by 2033 at a CAGR of 4.78% during the forecast period 2025–2033.

Japan’s growth of the testing, inspection & certification market is underpinned by its highly industrialized economy, stringent regulatory environment, and a culture of uncompromising quality. The Tokyo-Yokohama metropolitan area, as Japan’s largest industrial hub, is a focal point for TIC demand due to its concentration of heavy industries such as chemicals, machinery, transportation equipment, and oil refining, alongside Tokyo’s dominance in electronics and publishing. The Kansai region (Osaka-Kobe) and Chubu region (Nagoya) are equally significant, with Nagoya’s automotive and aerospace clusters and Osaka-Kobe’s steel and manufacturing sectors driving a continuous need for rigorous product testing and certification to meet both domestic and international standards.

Sector-wise, the automotive industry stands out as one of the major consumers of TIC services. Japan’s automotive sector, home to global giants like Toyota and Honda, relies on TIC for car certification, emissions testing, and compliance with evolving safety and environmental regulations. The rapid adoption of electric vehicles (EVs)—with battery-electric passenger vehicles reaching approximately 162,400 units by March 2023—has intensified the need for specialized TIC services for batteries, charging infrastructure, and new materials. Similarly, the electronics and semiconductor industries, centered in Tokyo, Osaka, and Nagoya, require extensive TIC support for product safety, electromagnetic compatibility, and quality assurance, especially as Japan remains a global leader in consumer electronics and advanced semiconductors.

Emerging sectors are also fueling new testing, inspection & certification market growth. The healthcare and pharmaceutical industries, particularly in urban centers like Tokyo and Osaka, require rigorous testing and certification to comply with Good Manufacturing Practice (GMP) and international standards such as ISO 13485:2016. The biotechnology sector, driven by Japan’s aging population and innovation in medical devices, further amplifies the need for TIC services to ensure product safety and regulatory compliance. Meanwhile, the infrastructure and construction sector, which dominates the TIC market and is projected to grow at a CAGR of 4.2%, is concentrated in major cities and is driven by ongoing urban redevelopment and earthquake resilience projects.

To Get more Insights, Request A Free Sample

Market Dynamics

Driver: Increasing complexity of products and supply chains in manufacturing industries

The Japan testing, inspection & certification market is being significantly shaped in 2024 by the increasing complexity of products and supply chains, especially in sectors like automotive, electronics, and precision machinery. As Japanese manufacturers introduce advanced technologies—such as autonomous driving systems, 5G-enabled devices, and smart factory robotics—the number of components requiring rigorous testing and certification has surged. For example, a single electric vehicle model now contains over 30,000 individual parts, each demanding traceability and compliance checks at multiple stages of production. This complexity extends to the supply chain, where Japanese manufacturers source components from more than 50 countries, necessitating robust inspection protocols to ensure that every imported part meets Japan’s stringent quality and safety standards. The Japan testing, inspection & certification market is responding with expanded laboratory capacity and digitalized tracking systems to manage this intricate web of suppliers and products.

In 2024, the Japan testing, inspection & certification market is witnessing a marked increase in demand for multi-stage and cross-border certification services. Manufacturers are now requiring TIC providers to conduct inspections not only at final assembly plants but also at upstream supplier facilities, both domestically and internationally. For instance, electronics manufacturers are conducting over 5,000 supplier audits annually to verify compliance with Japanese Industrial Standards and international benchmarks. The complexity of modern products, such as medical imaging devices or industrial automation systems, means that TIC providers must possess deep technical expertise and the ability to coordinate across multiple jurisdictions. This trend is driving investment in advanced data management platforms, real-time supply chain monitoring, and collaborative partnerships between Japanese TIC firms and global certification bodies, ensuring that the Japan testing, inspection & certification market remains agile and responsive to the evolving needs of manufacturers.

Trend: Expansion of TIC services in renewable energy and digital transformation sectors

A prominent trend in the Japan testing, inspection & certification market in 2024 is the rapid expansion of TIC services in renewable energy and digital transformation sectors. As Japan accelerates its transition toward a low-carbon economy, the number of solar, wind, and hydrogen projects requiring certification has grown substantially. In 2024, over 1,800 new renewable energy installations—including utility-scale solar farms and offshore wind turbines—underwent comprehensive testing and inspection to comply with national safety and environmental regulations. TIC providers are now offering specialized services such as grid integration testing, battery storage certification, and lifecycle emissions assessments, reflecting the increasingly technical and regulatory demands of the sector. The Japan market is also seeing a surge in demand for digital transformation services, with more than 2,500 industrial facilities adopting IoT-enabled monitoring and AI-driven analytics to optimize operational efficiency and regulatory compliance.

This trend is further reinforced by government initiatives and private sector investment in smart infrastructure and Industry 4.0 technologies. The Japan testing, inspection & certification market is responding by developing new protocols for cybersecurity certification, data privacy audits, and digital twin validation, particularly for critical infrastructure and manufacturing plants. In 2024, TIC providers are conducting over 4,000 cybersecurity assessments annually for energy, transportation, and financial services clients, ensuring that digital systems are resilient against evolving threats. The integration of digital tools into TIC workflows is enabling real-time monitoring, predictive maintenance, and automated compliance reporting, which are now standard requirements for clients in the renewable energy and digital sectors. This expansion is positioning the Japan testing, inspection & certification market as a key enabler of Japan’s green and digital transformation, offering stakeholders new opportunities for growth and innovation.

Challenge: Navigating Japan’s complex and frequently updated regulatory landscape efficiently

One of the most pressing challenges in the Japan testing, inspection & certification market in 2024 is the need to efficiently navigate Japan’s complex and frequently updated regulatory landscape. Regulatory authorities in Japan, such as the Ministry of Economy, Trade and Industry (METI) and the Pharmaceuticals and Medical Devices Agency (PMDA), regularly update standards to reflect technological advancements, safety concerns, and international harmonization efforts. In 2024 alone, over 600 regulatory amendments were introduced across sectors including automotive, electronics, and healthcare, requiring TIC providers and manufacturers to continuously adapt their compliance strategies. The Japan testing, inspection & certification market is therefore investing heavily in regulatory intelligence platforms, automated compliance tracking, and legal advisory services to help clients stay ahead of these changes and avoid costly delays or non-compliance penalties.

The challenge is particularly acute for multinational manufacturers and exporters, who must ensure that their products meet both Japanese and international standards. In the Japan market, TIC providers are now managing compliance for more than 12,000 product lines annually, each subject to a unique set of regulatory requirements. The frequent updates and sector-specific nuances of Japanese regulations demand a high level of expertise and agility from TIC professionals. In response, leading TIC firms are expanding their regulatory affairs teams, offering real-time regulatory updates, and developing customized compliance roadmaps for clients. This proactive approach is essential for market stakeholders seeking to minimize risk, maintain market access, and capitalize on new opportunities in Japan’s highly regulated environment. The ability to efficiently navigate this regulatory complexity is becoming a key differentiator in the Japan testing, inspection & certification market, driving investment in technology, talent, and strategic partnerships.

Segmental Analysis

By Service Type

Testing services currently lead the Japan testing, inspection & certification market, controlling over 42.32% market share. The major testing services include product safety testing, performance testing, durability testing, chemical analysis, and electromagnetic compatibility testing. These services are essential for ensuring that products meet both domestic and international standards before reaching consumers. In the Japan market, product safety testing is particularly prominent in sectors such as automotive, electronics, and healthcare, where regulatory compliance is non-negotiable. For example, automotive manufacturers rely on crash tests, emissions testing, and component reliability assessments, while electronics companies focus on electromagnetic compatibility and electrical safety.

Key end users that opt for these testing services are diverse, but the most significant include automotive manufacturers, electronics producers, healthcare device companies, and industrial machinery firms. In the Japan testing, inspection & certification market, these end users are driven by the need to ensure product reliability, safety, and compliance with evolving regulations. Automotive and electronics sectors, in particular, require extensive testing due to the complexity and integration of advanced technologies in their products. Healthcare device manufacturers also depend on rigorous testing to meet the strict standards set by regulatory authorities. This demand for comprehensive testing services is further amplified by Japan’s export-oriented economy, where meeting international certification requirements is crucial for accessing global markets.

By Application

Among all applications, quality and safety take the lead in the Japan testing, inspection & certification market, holding over 58.65% market share. This dominance is a direct reflection of Japan’s longstanding commitment to product excellence and consumer protection. In the Japan market, quality and safety testing encompasses a broad spectrum of activities, including material analysis, functional testing, and risk assessment. These processes are integral to ensuring that products not only comply with regulatory requirements but also meet the high expectations of Japanese consumers, who are known for their demand for reliability and safety.

The emphasis on quality and safety is particularly pronounced in sectors such as automotive, electronics, and healthcare, where product failures can have significant consequences. In the Japan testing, inspection & certification market, manufacturers are required to conduct multiple rounds of testing and validation before products are approved for sale. This rigorous approach is supported by both government regulations and industry standards, which mandate comprehensive documentation and traceability. The focus on quality and safety also extends to export markets, as Japanese products are often held to higher standards internationally. As a result, companies invest substantial resources in testing and certification to maintain their reputation for excellence and to ensure market access worldwide.

By End User

Consumer Goods & Retail is the largest end user of the Japan testing, inspection & certification market, controlling over 23% market share. This sector’s prominence is driven by the sheer volume and diversity of products that require testing before reaching consumers. In the Japan market, consumer goods such as electronics, household appliances, toys, textiles, and food products are subject to stringent safety and quality assessments. The high frequency of product launches and the rapid turnover of inventory in retail environments necessitate continuous testing to ensure compliance with evolving regulations and consumer expectations.

Major products from the consumer goods and retail domain that demand higher scrutiny and testing include children’s toys, electrical appliances, cosmetics, and packaged foods. In the Japan testing, inspection & certification market, these products are tested for factors such as chemical safety, electrical hazards, allergen content, and labeling accuracy. The rise of e-commerce and the increasing import of foreign goods have further intensified the need for robust testing protocols to prevent the entry of substandard or counterfeit products. Retailers and manufacturers alike rely on comprehensive TIC services to safeguard brand reputation, protect consumers, and maintain compliance with both domestic and international standards.

By Solution Type

Most of the testing, inspection & certification in Japan is conducted through in-house services, accounting for over 58.48% market share. The preference for in-house services in the Japan testing, inspection & certification market is rooted in the desire for greater control over quality assurance processes. Japanese companies, especially large manufacturers, value the ability to closely monitor and manage every stage of product development and testing. In-house testing allows for immediate feedback, rapid troubleshooting, and seamless integration with internal quality management systems. This approach is particularly advantageous in industries where proprietary technologies and confidential processes are involved, as it minimizes the risk of intellectual property leakage.

Key factors enabling major end users to opt for in-house services over outsourcing include the availability of advanced testing infrastructure, skilled personnel, and established quality management frameworks. In the Japan testing, inspection & certification market, leading automotive and electronics companies have invested heavily in state-of-the-art laboratories and testing facilities, enabling them to conduct a wide range of assessments internally. Additionally, the cultural emphasis on precision and continuous improvement supports the in-house model, as companies can quickly adapt to regulatory changes and implement corrective actions. The ability to maintain strict confidentiality and align testing protocols with internal standards further reinforces the dominance of in-house services among major Japanese manufacturers.

Customize This Report + Validate with an Expert

Access only the sections you need—region-specific, company-level, or by use-case.

Includes a free consultation with a domain expert to help guide your decision.

To Understand More About this Research: Request A Free Sample

Top Players in Japan Testing, Inspection & Certification Market

- SGS SA

- Bureau Veritas SA

- Intertek Group plc

- DEKRA SE

- DNV

- TÜV SÜD

- TUV Rheinland AG

- Cotecna Inspection Japan Co., Ltd.

- AmSpec Group

- Apave Japan Co.,Ltd

- American Bureau of Shipping (ABS)

- UL LLC

- Japan Quality Assurance Organization (JQA)

- Japan Testing Laboratory Co., Ltd. (JTL)

- Japan Inspection Co. Ltd.

- Other Prominent players

Market Segmentation Overview

By Service Type

- Testing Services

- Inspection Services

- Certification Services

- Training

- Consultancy

By Solution Type

- In-house Services

- Outsource Services

By Application

- Quality and Safety

- Production Evaluation

- Industrial Inspection

- System Certification

- Others

By End User

- Consumer Goods & Retail

- Food & Agriculture

- Oil & Gas

- Construction & Engineering

- Water and Wastewater

- Education

- Energy & Chemistry

- Industrial Product Manufacturing

- Transportation (Rail & Aerospace) and Tourism

- Automotive

- Other

LOOKING FOR COMPREHENSIVE MARKET KNOWLEDGE? ENGAGE OUR EXPERT SPECIALISTS.

SPEAK TO AN ANALYST

.svg)