Spout Pouch Market: By Product (Beverages, Syrups, Energy Drinks, and others); Component (Cap, straw, and others); Pouch Size (Less Than 200 ML, 200 to 500 ML, and others); Material (Plastic, Aluminum, Paper, and others); Closure Type (Screw, Flip-Flop, and others); End User (Food and Beverages, Cosmetics and Personal Care and others; and Region—Industry Dynamics, Market Size, Opportunity and Forecast For 2026-2035

- Last Updated: 13-Jan-2026 | | Report ID: AA0122121

Market Snapshot

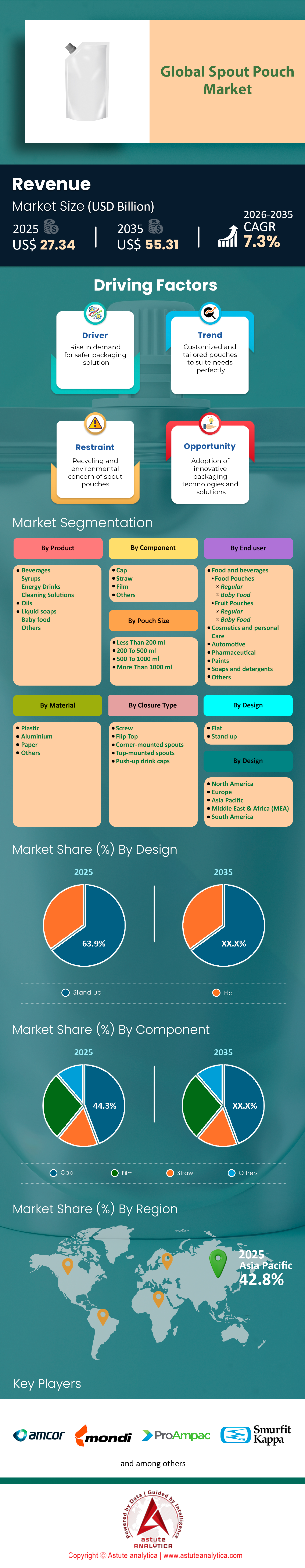

Spout pouch market was valued at US$ 27.34 billion in 2025 and is projected to hit the market valuation of US$ 55.31 billion by 2035 at a CAGR of 7.3% during the forecast period 2026–2035.

Key Findings Shaping the Market

- By Product Type, beverages constitute more than 40.5% market share of the spout pouch market.

- By size, less than 200 ml leads the market with revenue share of 42.4% in the spout pouch market.

- By end users, food and beverage (F&B) industry accounts for an astonishing 43.1% share of the market.

- By material, plastic emerged as the most dominantly used material in the spout pouch production.

- Asia Pacific is holding lion’s share of 42.80% in the global market.

The global packaging sector is currently witnessing a shift where rigidity is rapidly giving way to flexibility. The spout pouch has emerged as the protagonist in this narrative, effectively bridging the gap between the low cost of flexible films and the functionality of rigid bottles. At its core, a spout pouch is a laminated flexible package fitted with a resealable plastic spout, designed to hold liquids ranging from viscous baby food to industrial chemicals. However, to view it merely as a container is to miss the economic reality; it is a logistical tool that reduces weight, carbon footprints, and freight costs.

The spout pouch market is no longer in a nascent experimental phase, it is a mature, high-stakes arena defined by USD 50 million CAPEX investments and 12 billion pack capacities. With stakeholders navigating USD 1,300+ raw material costs and strict carbon taxes, the spout pouch offers the only viable path forward: a package that uses less material, costs less to ship, and performs with the reliability of a rigid bottle. As 2025 progresses, the data indicates that this format will continue to cannibalize the market share of glass and rigid plastic, driven by the relentless pursuit of supply chain efficiency.

To Get more Insights, Request A Free Sample

What Are the Primary Catalysts Fueling Demand for Spout Pouch Market?

The current demand trajectory is not accidental; it is being forced by a convergence of legislative pressure and logistical necessity. The primary driver is the urgent need to decarbonize supply chains. In 2024, the UK Plastic Packaging Tax rate climbed to £217.85 per tonne, with a scheduled increase to £223.69 per tonne in April 2025. This fiscal pressure compels manufacturers to abandon heavy rigid plastics. Furthermore, the logistical argument is irrefutable. A shipment of 10,000 units of 500ml product in spout pouches weighs only 80 kg, compared to 300 kg for rigid bottles. This 220 kg weight reduction per shipment directly translates to lower fuel consumption and freight costs. Consequently, companies are adopting these pouches to protect margins against rising energy prices.

Where is the Global Spout Pouch Consumption is Heavily Concentrated?

While Europe leads in regulatory-driven adoption, the sheer volume of consumption in the spout pouch market is concentrated heavily in the Asia-Pacific region. Emerging economies are driving unit sales to astronomical levels. For instance, in 2024, Indonesia recorded baby food packaging retail volumes of 1.3 billion units, dwarfing many Western markets. Similarly, Thailand saw volumes reach 542 million units.

The Middle East is also emerging as a high-growth pocket, with the United Arab Emirates consuming 33 million units in the same period. This geographic split creates a dual-speed market: the West focuses on sustainability and mono-material innovation, while the East focuses on high-speed, high-volume production to feed a growing middle class.

Which Application Areas Are witnessing the Highest Adoption?

The application landscape is diversifying rapidly across the spout pouch market. Packaging of Baby food and toddler nutrition remain the bedrock of this market, with global sales of liquid baby food products exceeding 80 million units annually as of August 2025. Wherein, parents prefer the safety and convenience of the format.

However, the most dynamic growth is occurring in the home and personal care sectors. In May 2024, UFlex commercially launched a 5-liter spouted pouch for liquid detergent, signaling a shift toward large-format refill packs that replace rigid jugs. Additionally, the industrial sector is testing the waters; new designs now include 10-liter double spout pouches for water filtration systems, proving that spout pouches can handle heavy-duty applications previously reserved for jerry cans.

Who Are the Largest Producers Orchestrating Supply?

The supply side of the spout pouch market is controlled by a mix of legacy packaging giants and agile specialists who are aggressively expanding capacity. Amcor remains a titan in this space, reporting Net Sales of USD 3.35 billion in Q1 FY2025 alone, with its Flexibles segment contributing USD 2.55 billion. Their influence is set to grow further following the acquisition of Berry Global, which is projected to yield USD 650 million in total synergies.

UFlex is another powerhouse in the spout pouch market, boasting a total packaging film manufacturing capacity of 636,160 metric tons per annum (MTPA). Their recent expansion includes an aseptic liquid packaging capacity of 12 billion packs per annum, positioning them to dominate the liquid sector. Gualapack also remains a critical player, particularly in sustainability, having generated 29,878 kWh of renewable energy to power its production lines.

Why is China the Lynchpin of the Global Spout Pouch Market?

China’s role extends beyond just consumption, it is the factory floor of the world for flexible packaging due to critical raw material advantages. The economics of resin pricing heavily favors Chinese production. In March 2025, the price of High-Density Polyethylene (HDPE) in China was recorded at USD 1,155 per metric ton. In stark contrast, prices in the USA stood at USD 1,242 and in the UK at USD 1,305. This pricing disparity allows Chinese manufacturers to offer significantly lower unit costs.

Furthermore, with Polyethylene futures trading at approximately 6,411 CNY per tonne in early 2026, China continues to maintain a competitive edge in material sourcing, making it the primary hub for export-oriented empty pouch production.

How Are Material Innovations Affecting Adoption?

The spout pouch market is moving away from multi-polymer structures that are hard to recycle toward advanced mono-material laminates that do not compromise on durability. Innovation is now measured in microns and barrier properties. For example, UFlex’s new large-format pouches utilize a robust structure containing a 12-micron PET layer and a 15-micron Biaxially Oriented Nylon (BON) layer, reinforced by a 165-micron Natural PE inner sealant.

These specifications ensure that the pouch can withstand the hydraulic shock of being dropped, addressing the historic weakness of flexible packaging. Furthermore, companies like All4Labels have retrofitted machinery with LED curing technology, reducing CO2 emissions by 2,000 tons annually, proving that material science is evolving alongside process engineering to meet green mandates.

What Do Recent Patent Developments Reveal About the Future of Spout Pouch?

Intellectual property filings serve as a compass for the spout pouch market's direction, and the data suggests a surge in R&D activity. In the third quarter of 2024 alone, the global packaging industry filed 10,389 patent applications. Tetra Laval International led the charge with 140 patents, followed closely by Krones with 102 patents. This intense activity is not limited to traditional players; Samsung holds 10,084 granted patents in the U.S., hinting at future integrations of smart packaging technologies.

Specific product patents, such as US11919686B1 granted to Packaging Corporation of America for a liquid-filled bag container, indicate that the industry is actively solving technical challenges related to filling mechanics and closure integrity.

Which Recent Trends Are Shaping the Market Landscape?

Two distinct trends are reshaping the spout pouch market in 2025: extreme speed and large-format expansion. To meet the demand of billions of units, filling technology has become hyper-efficient. The UFlex Asepto Speed 25000 machine now processes 25,000 packs per hour, a throughput previously thought impossible for flexible formats.

Simultaneously, machinery versatility is improving; Rezpack’s latest units can handle pouch widths between 60 mm and 120 mm and lengths up to 200 mm, consuming only 2 kW of power. This efficiency allows brands to run diverse SKUs on a single line. Additionally, the shift to "jumbo" formats is evident with the introduction of 40 mm diameter spouts for 10-liter bags, moving the market beyond single-serve beverages into the bulk commodity space.

Segmental Analysis

By Product Type: Spout Pouches Being Heavily Consumed in Packaging of Beverages

By Product Type, beverages constitute more than 40.5% market share of the spout pouch market, driven by a definitive shift toward lightweight, shatterproof packaging that caters to active lifestyles. This dominance is underpinned by major sustainability initiatives from industry giants who are replacing rigid glass and metal formats with flexible alternatives to reduce logistical costs and environmental impact. For instance, Amcor recently showcased its Liquiflex AmPrima solution, a pouch designed for bulk liquids that delivers a verified 79% reduction in carbon footprint and 84% less water consumption compared to traditional cans. The segment is further bolstered by the surge in "Ready-to-Drink" (RTD) coffee and cocktails, a category projected to grow at a 13.4% CAGR, where brands are adopting pouches for their unique ability to be frozen and safely used in venues where glass is restricted.

In the sports nutrition landscape, the demand for ergonomic liquid delivery systems has solidified this segment's lead in the spout pouch market. Gualapack has reported increasing production volumes for "energy gels in pouches," directly capitalizing on the need for portable hydration during endurance sports. Furthermore, Mondi has aggressively expanded its portfolio with the StripPouch system, which utilizes 70% less material than rigid plastic bottles, offering a compelling financial incentive for beverage concentrate manufacturers facing rising plastic taxes. This transition is not merely aesthetic but functional; Mondi’s new FunctionalBarrier Paper now offers high-barrier protection against oxygen and moisture for powdered drinks, ensuring that the beverage segment remains the primary revenue engine for the spout pouch industry through continuous material innovation.

By Size: Single-Serve Portability Driving Sub-200ml Pouch Dominance

By size, less than 200 ml leads the spout pouch market with a revenue share of 42.4%, anchored by the explosive popularity of the baby food and single-serve healthy snack sectors. This size range has become the global industry standard for calorie-controlled nutrition, where portability and resealability are non-negotiable requirements for parents and on-the-go consumers. The commercial viability of this segment is best exemplified by GoGo squeeZ, a market leader that generates over $200 million in annual sales exclusively through small-format pouches. In 2024, the brand expanded its portfolio with Active Fruit Blend with Electrolytes in the 90g to 110g range, further cementing the sub-200ml pouch as the preferred vehicle for functional snacking.

The dominance of this segment in the spout pouch market is also reinforced by significant logistical and material advantages that drive manufacturer adoption. Industry data reveals that pouches now account for approximately 30% of all baby food packaging, rapidly cannibalizing the market share of traditional glass jars due to superior safety profiles. Switching a standard 100ml serving from a glass jar to a spout pouch results in a packaging weight reduction of over 85%, which drastically lowers transport emissions for high-volume, small-unit shipments. To meet this specific demand, Mondi has optimized its "re/cycle SpoutedPouch" production lines specifically for the 70ml to 250ml capacity range, ensuring that infrastructure aligns with the high-velocity consumption patterns of the single-serve market.

By End Users: F&B industry Emerged As Unrivaled Adopter of Flexible Spout Packaging

By end users, the food and beverage (F&B) industry accounts for an astonishing 43.1% share of the spout pouch market, serving as the primary catalyst for the widespread transition from rigid containers to flexible refills and shelf-stable sauces. The sheer scale of this sector is highlighted by the Flexible Packaging Association (FPA), which confirms that food packaging constitutes 52% of the total flexible packaging market, dwarfing all other end-use sectors combined. Major conglomerates are aggressively pivoting to this format to meet environmental goals; Kraft Heinz, for example, has committed to making 100% of its packaging globally recyclable, reusable, or compostable by 2025, rolling out spouted refill pouches for high-volume products like ketchup and mayonnaise to achieve these sustainability targets.

Beyond sustainability, the F&B sector relies on spout pouches market to combat food waste and extend shelf life through advanced processing technologies. Le Sauce & Co. recently shifted its entire product line to spout pouches after internal research indicated that 92% of consumers discard unused jarred sauces; the flexible format allows for smaller, precise portions that eliminate this waste. To support these applications, Mondi developed the RetortPouch Recyclable, a breakthrough innovation capable of withstanding high-temperature sterilization for wet food products. Sonoco’s 2025 financial outlook further validates this segmental dominance, revealing that their "Consumer Packaging" unit, which is heavily integrated with food industry clients, now represents 66% of their total business, driven by the relentless demand for flexible food solutions.

Customize This Report + Validate with an Expert

Access only the sections you need—region-specific, company-level, or by use-case.

Includes a free consultation with a domain expert to help guide your decision.

By Material: High-Barrier Plastic Mono-Materials Securing Supremacy in Spout Pouch Market

By material, plastic emerged as the most dominantly used material in the spout pouch production, currently holding an estimated 44.0% market share due to its unmatched barrier properties and cost-effectiveness. While paper alternatives are emerging, plastic maintains its stronghold through the rapid evolution of "mono-material" technologies, such as Polyethylene (PE) and Polypropylene (PP), which offer the necessary durability for liquids while solving historical recyclability issues. Amcor’s AmPrima PE Plus spout pouch solution exemplifies this technological leap, offering a 46% reduction in carbon footprint compared to standard laminates and achieving pre-qualification by How2Recycle for curbside recycling, thereby neutralizing the primary environmental argument against plastic usage.

The material's dominance in the spout pouch market is further secured by its unique ability to withstand rigorous processing conditions that other substrates cannot yet match. Gualapack’s Pouch5 is a 100% mono-material PP pouch designed for hot-filling and pasteurization, a critical requirement for shelf-stable liquid foods that ensures plastic remains indispensable. Mondi has similarly reinforced plastic's viability with its StripPouch solution, a mono-material PE format that has achieved a 100% recyclability rating from cyclos-HTP. Data from European markets indicates that mono-material PE films are now replacing mixed plastics at an accelerated rate, with companies like Werner & Mertz adopting these advanced plastic solutions to close the recycling loop, ensuring that plastic remains the functional backbone of the spout pouch industry.

To Understand More About this Research: Request A Free Sample

Regional Analysis

Asia Pacific Dominates Global Volume Through Massive Production Capacity And Consumer Demand

Asia Pacific currently commands a staggering 42.80% of the global spout pouch market revenue share, a dominance built on the twin pillars of aggressive manufacturing and exploding retail consumption. The region effectively functions as the world's factory floor, leveraging raw material advantages that competitors cannot match. In March 2025, the price of High-Density Polyethylene (HDPE) in China sat at just USD 1,155 per metric ton, significantly lower than Western benchmarks. Manufacturers pass these savings downstream, fueling massive output. UFlex, a key regional player, recently expanded its aseptic liquid packaging capacity in India to an impressive 12 billion packs per annum.

Simultaneously, consumer uptake in Southeast Asia is rewriting volume expectations. Indonesia alone recorded retail volumes of 1.3 billion units for baby food packaging in 2024, while Thailand followed with 542 million units. Such figures confirm that the region is not merely exporting empty pouches but consuming filled product at an unprecedented rate.

North America Accelerates Adoption Driven By Lifestyle Convenience and High Material Costs

North America holds the second-largest position in the spout pouch market, driven by a corporate imperative to reduce logistical overheads in a high-cost environment. Domestic resin prices are a significant catalyst for this shift; with HDPE trading at USD 1,242 per metric ton in the USA, companies are abandoning heavy rigid containers to protect margins. Amcor, heavily exposed to this market, reported Net Sales of USD 3.35 billion in Q1 FY2025, underscoring the profitability of the flexible segment here. Innovation also sustains this growth, as evidenced by Packaging Corporation of America securing Patent US11919686B1 for advanced liquid-filled bag containers.

These developments indicate a market moving toward premium, value-added spouted formats. The region prioritizes "on-the-go" convenience, pushing the adoption of single-serve pouches for everything from apple sauce to protein gels.

Europe Prioritizes Sustainability Mandates and Carbon Taxation To Reshape Packaging Standards

Europe maintains its stronghold in the spout pouch market through rigid legislative frameworks that essentially outlaw inefficiency. The UK Plastic Packaging Tax, rising to £223.69 per tonne in April 2025, has forced a continent-wide migration toward lighter packaging formats. Financial pressures are compounded by raw material spikes, with UK HDPE prices hitting USD 1,305 per metric ton, making spout pouches the only economically viable option for many liquid producers.

Corporate ESG commitments are equally influential in this region. Gualapack’s European operations have focused heavily on reducing their footprint, reporting 34,000 metric tons of CO2 emissions, while All4Labels successfully mitigated 2,000 tons of CO2 annually through technology retrofits. European demand is less about volume expansion and more about material circularity and meeting strict carbon reduction targets.

Recent Developments Announced By Companies in Spout Pouch Market

- Swiss Pack FORMIL Refill Pouch: Swiss Pack Europe, with Algramo for Lidl, launched refillable FORMIL spout pouches, winning the Innovation Gallery Award at Packaging Innovations & Empack 2025 (Feb). These enable in-store laundry detergent refills, slashing plastic waste via circular design.

- RJ Flexpack Stand-Up Pouches: RJ Flexpack announced advanced stand-up spout pouches (Jun 2025) using PET/NY/PE multi-layers for leak-proof liquids/semi-solids in beverages/sauces, meeting FDA/EU standards.

- Guangdong Nanxin Digital Innovations: Guangdong Nanxin Print & Packaging unveiled eco-material spout pouches with digital printing (Dec 2025), boosting sustainability for food/beverage amid rising demand.

- GDO K Laminated Spouts: Dongguan OK Packaging topped 2025 rankings for high-barrier laminated spouted pouches, FDA/BRC/ISO certified for global liquids/pastes.

- Amcor Pharma Flexibles: Amcor displayed recyclable, patient-centric spout-compatible pharma laminates at CPHI Frankfurt (Oct 2025), enhancing moisture protection.

Top Companies in Spout Pouch Market

- Amcor Ltd.

- The DOW Chemical Company

- Mondi Group

- Berry Plastic Corporation

- Smurfit Kappa Group

- Bemis Company Inc.

- Essentra PLC

- Bischof & Klein GmbH & Co. KG

- Coating Excellence International

- HOD Packaging and enterprises Ltd.

- Printpack Inc.

- ProAmpac

- Sealed Air Corporation

- Sonoco Products Company

- Winpak Ltd.

- Glenroy Inc

- Logos Pack

- Color Flex

- Other Prominent Players

CPG Manufacturers

- Nestlé

- Procter & Gamble

- Clorox

- L'Oreal USA

- Krafts Heinz

- Tyson Foods Inc

- Kraft Foods Inc

- Unilever

- The Pepsi Bottling Group

- Other Prominent Players

Market Segmentation Overview:

By Product

- Beverages

- Syrups

- Energy Drinks

- Cleaning Solutions

- Oils

- Liquid soaps

- Baby food

- Others

By Component

- Cap

- Straw

- Film

- Others

By Pouch Size

- Less Than 200 ML

- 200 To 500 ML

- 500 To 1000 ML

- More Than 1000 ML

By Material:

- Plastic

- Aluminium

- Paper

- Others

By Closure Type

- Screw

- Flip Top

- Corner-mounted spouts

- Top-mounted spouts

- Push-up drink caps

By Design

- Flat

- Stand Up

By End user

- Food and beverages

- Food Pouches

- Regular

- Baby Food

- Fruit Pouches

- Regular

- Baby Food

- Food Pouches

- Cosmetics and personal Care

- Automotive

- Pharmaceutical

- Paints

- Soaps and detergents

- Others

By Region

- North America

- The U.S.

- Canada

- Mexico

- Europe

- Western Europe

- The UK

- Germany

- France

- Italy

- Spain

- Rest of Western Europe

- Eastern Europe

- Poland

- Russia

- Rest of Eastern Europe

- Western Europe

- Asia Pacific

- China

- India

- Japan

- South Korea

- Australia & New Zealand

- ASEAN

- Rest of APAC

- Middle East & Africa (MEA)

- UAE

- Saudi Arabia

- South Africa

- Rest of MEA

- South America

- Argentina

- Brazil

- Rest of South America

REPORT SCOPE

| Report Attribute | Details |

|---|---|

| Market Size Value in 2025 | US$ 27.34 Bn |

| Expected Revenue in 2035 | US$ 55.31 Bn |

| Historic Data | 2020-2024 |

| Base Year | 2025 |

| Forecast Period | 2026-2035 |

| Unit | Value (USD Bn) |

| CAGR | 7.3% |

| Segments covered | By Product, By Component, By Pouch Size, By Material, By Closure Type, By Design, By End User, By Region |

| Key Companies | Amcor Ltd., The DOW Chemical Company, Mondi Group, Berry Plastic Corporation, Smurfit Kappa Group, Bemis Company Inc., Essentra PLC, Bischof & Klein GmbH & Co. KG, Coating Excellence International, HOD Packaging and enterprises Ltd., Printpack Inc., ProAmpac, Sealed Air Corporation, Sonoco Products Company, Winpak Ltd., Glenroy Inc, Logos Pack, Color Flex, Other Prominent Players |

| Customization Scope | Get your customized report as per your preference. Ask for customization |

FREQUENTLY ASKED QUESTIONS

Spout pouch market was valued at US$ 27.34 billion in 2025 and is projected to hit the market valuation of US$ 55.31 billion by 2035 at a CAGR of 7.3% during the forecast period 2026–2035.

Spout pouches offer massive freight savings. A shipment of 10,000 units weighs only 80 kg in flexible pouches compared to 300 kg in rigid bottles. This 220 kg weight reduction significantly lowers fuel consumption and shipping overheads.

Legislative pressure is a primary driver. With the UK Plastic Packaging Tax rising to £223.69 per tonne in April 2025, manufacturers are forced to adopt lighter, lower-carbon formats like mono-material pouches to mitigate tax liabilities and meet ESG goals.

Asia Pacific holds the lion’s share of 42.80%. This dominance is fueled by China’s raw material advantage—with HDPE prices at USD 1,155 per metric ton—and high consumption volumes in markets like Indonesia (1.3 billion baby food units).

The spout pouch market is shifting toward extreme speed and larger formats. UFlex’s new machinery now achieves filling speeds of 25,000 packs per hour, while product designs have expanded to include 10-liter double-spout pouches for heavy-duty industrial applications.

The Food and Beverage (F&B) industry accounts for 43.1% of the market share. This segment is anchored by the baby food category, which sees over 80 million units in annual sales, and the rising demand for liquid detergent refills.

LOOKING FOR COMPREHENSIVE MARKET KNOWLEDGE? ENGAGE OUR EXPERT SPECIALISTS.

SPEAK TO AN ANALYST

.svg)