U.S. Carbon Steel Nail Market: By Nail Type (Common Nails, Box Nails, Finishing Nails, Brad Nails, Duplex Nails, Ring Shank Nails, Masonry Nails, Others); Size (Short Nails (Below 1 inch / 25mm), Medium Nails (1-2.5 inches / 25-64mm), Long Nails (2.5-4 inches / 64-102mm), Extra-Long Nails (Above 4 inches / 102mm)); Packaging (Bulk, Bundled, Collated (Strips/Coils)); Application (Framing, Roofing, Drywall Installation, Flooring, Pallet and Crate Assembly, Fencing and Decking, Others); End Users (Framing, Roofing, Drywall Installation, Flooring, Pallet and Crate Assembly, Fencing and Decking, Others); Distribution Channel (Online, Offline (Direct Sales, Distributors & Wholesalers, Retail Stores, Hardware Stores, Home Improvement Chains); Region—Market Size, Industry Dynamics, Opportunity Analysis and Forecast for 2025–2033

- Last Updated: 23-May-2025 | | Report ID: AA05251327

Market Scenario

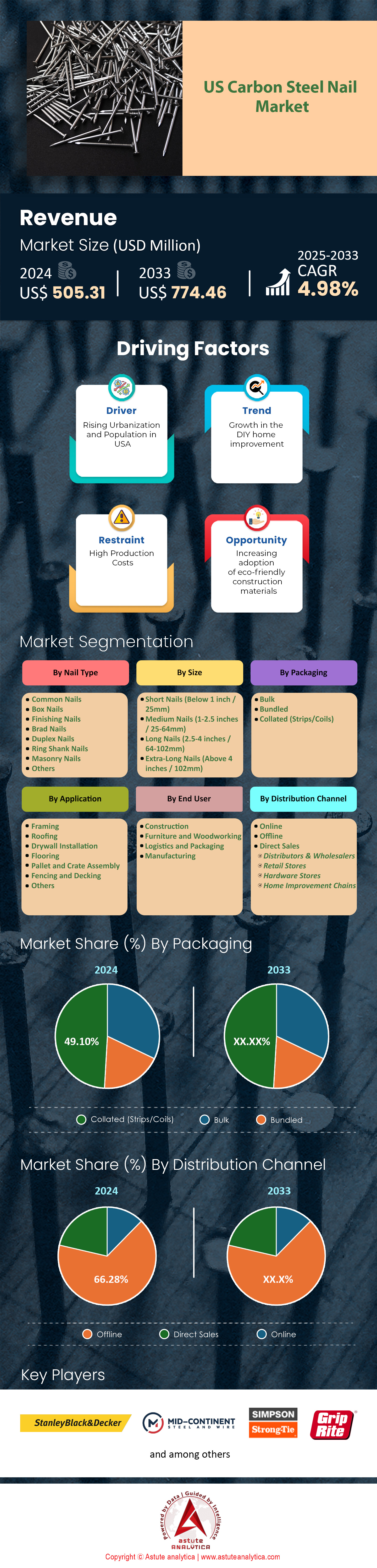

U.S. carbon steel nail market was valued at US$ 505.31 million in 2024 and is projected to hit the market valuation of US$ 774.46 million by 2033 at a CAGR of 4.98% during the forecast period 2025–2033.

The US carbon steel nail market in 2024 is witnessing dynamic growth, driven by robust demand from the construction, furniture, and manufacturing sectors. The construction industry, in particular, remains the largest consumer of carbon steel nails, with significant activity in states like California, Texas, Florida, and New York. These states are leading in consumption due to their large-scale residential and commercial construction projects, including housing developments and infrastructure upgrades. For example, Texas alone has seen a surge in housing starts, with over 200,000 new units under construction in 2024, creating a substantial demand for framing and roofing nails. Similarly, Florida’s ongoing hurricane recovery efforts have increased the need for durable carbon steel nails in roofing and structural repairs. The furniture manufacturing sector also contributes significantly, with carbon steel nails being a preferred choice for assembling wooden furniture due to their strength and cost-effectiveness.

On the production side, manufacturers in the US carbon steel nail market are focusing on enhancing efficiency and meeting the growing demand for specialty nails. Companies like Mid Continent Steel and Wire, one of the largest domestic producers, have increased their output of galvanized and heat-treated carbon steel nails, which are essential for outdoor and heavy-duty applications. Domestic production is complemented by imports, primarily from China and Vietnam, which cater to the lower-cost segment of the market. In 2024, the US imported over 500,000 tons of steel nails, with a significant portion being carbon steel variants. Packaging innovations are also shaping the market, with manufacturers offering bulk packaging for contractors and smaller, retail-friendly packs for DIY consumers. The rise of e-commerce platforms has further streamlined the distribution of carbon steel nails, making them more accessible to end users.

Looking ahead, the US carbon steel nail market is expected to grow steadily, supported by federal infrastructure investments and the increasing popularity of modular construction. The demand for specific nail types, such as ring-shank nails for high-stress applications, is projected to rise. Additionally, the DIY market is expanding, with over 60 million US households engaging in home improvement projects in 2024, driving retail sales of carbon steel nails. Manufacturers are also exploring sustainable production practices, such as using recycled steel, to align with environmental regulations and consumer preferences. This combination of factors positions the US carbon steel nail market for sustained growth and innovation in the coming years.

To Get more Insights, Request A Free Sample

Market Dynamics

Driver: High Construction Activity in Texas, California, Florida, and New York

The US carbon steel nail market has experienced substantial growth in 2024, primarily fueled by the robust construction activities in states like Texas, California, Florida, and New York. Texas, with over 200,000 housing units under active construction, leads the charge in framing and roofing applications that demand high volumes of carbon steel nails. The state's mix of urban expansion and suburban developments has created a consistent need for durable fastening solutions. Similarly, California’s focus on rebuilding after wildfire damage and ongoing real estate developments has positioned it as another significant consumer of carbon steel nails. Florida, driven by hurricane recovery and infrastructure upgrades, has seen an increase in roofing and structural repair needs. New York follows closely, with significant investments in commercial construction and urban housing projects. This localized demand has prompted manufacturers and distributors to allocate significant resources to these high-consuming states, ensuring market availability and competitive pricing.

The demand for US carbon steel nail market in these states reflects the diverse construction requirements across urban, coastal, and suburban geographies. In addition to framing and roofing, heavy-duty nails such as galvanized and spiral-shank variants have been in high demand for outdoor and weather-resistant applications. For example, Florida’s coastal construction projects require corrosion-resistant nails to withstand high humidity and salt exposure. These regional needs have led manufacturers to tailor production, focusing on specific nail types and sizes suited for localized conditions. Bulk packaging formats catering to contractors are particularly popular, with shipments exceeding 50,000 metric tons annually to these states. In 2024, distributors have also prioritized maintaining consistent inventory levels in these regions to meet the fast-paced construction timelines, illustrating how the US carbon steel nail market aligns itself with the country’s most construction-active states.

Trend: Growth in E-Commerce Sales for Smaller, Retail-Friendly Nail Packaging

In 2024, the US carbon steel nail market has seen a notable uptick in e-commerce sales, driven by the demand for smaller, retail-friendly packaging. The rise of do-it-yourself (DIY) projects among homeowners and small-scale contractors is a major contributor to this trend. With over 60 million households in the US engaging in home improvement projects this year, smaller packs of carbon steel nails tailored for retail customers have seen strong adoption. E-commerce platforms like Amazon, Home Depot, and Lowe’s have become critical distribution channels, offering convenient delivery options and competitive pricing. The availability of detailed product descriptions, customer reviews, and size guides online has further streamlined the purchasing process, enabling customers to make informed decisions. This shift has encouraged manufacturers to invest in eco-friendly packaging and offer varied nail sizes to match DIY needs, helping expand market reach beyond traditional contractor-focused distribution.

E-commerce has also enabled smaller manufacturers and niche brands to compete effectively in the US carbon steel nail market. By reducing dependency on physical retail stores, companies can directly reach consumers nationwide, including in rural areas where brick-and-mortar stores may have limited inventory. For instance, niche producers specializing in galvanized or weather-resistant carbon steel nails have successfully marketed their products to DIY enthusiasts seeking higher-quality options for outdoor projects. Additionally, the ability to offer bulk discounts online has attracted smaller contractors who prefer retail-friendly packaging but require multiple units for mid-sized projects. In response, manufacturers have optimized their supply chains to handle direct-to-consumer shipments, with e-commerce sales of carbon steel nails estimated to exceed 100,000 metric tons in 2024. This trend underscores the growing importance of online platforms in reshaping distribution strategies and enabling the industry to cater to diverse customer segments.

Challenge: Competition from Low-Cost Imports, Especially from China and Vietnam

The US carbon steel nail market continues to face significant challenges from low-cost imports, particularly from China and Vietnam. In 2024, imports of carbon steel nails exceeded 500,000 tons, with a significant portion sourced from these two countries. These imports cater to the low-cost segment of the market, which appeals to budget-conscious contractors and wholesale distributors. Chinese and Vietnamese manufacturers leverage lower production costs, including cheaper labor and materials, to supply competitively priced nails. Such imports have exerted downward pressure on domestic pricing, forcing US producers to reevaluate cost structures. The situation is further exacerbated by the variety of imported nails available, including galvanized and heat-treated options, which are often perceived as comparable in quality to domestic products but offered at significantly lower prices.

Manufacturers in the US carbon steel nail market have responded by focusing on premium product segments and emphasizing the superior quality of domestically produced carbon steel nails. For example, heat-treated and ring-shank nails, which offer enhanced durability and holding power, are being positioned as premium solutions for demanding applications like heavy-duty construction. However, the challenge persists, as large-scale contractors often prioritize cost savings over product origin. In response, the US government has implemented anti-dumping duties and tariffs on certain steel imports, but these measures have not fully offset the competitive advantage of imported nails. This has led some domestic producers to explore strategic partnerships, improve operational efficiency, and invest in automation to reduce production costs. Despite these challenges, the market remains resilient, with domestic manufacturers continuing to find ways to compete in an increasingly price-sensitive environment.

Segmental Analysis

By Nail Type: Common Nails Control Over 27.62% Market Share in the US Carbon Steel Nail Market

Common nails hold a dominant 27.62% share of the market in 2024 due to their unmatched versatility and widespread use across construction and DIY applications. These nails are the backbone of general-purpose construction, particularly in framing, carpentry, and woodworking. Contractors and builders rely on common nails for their strength, durability, and cost-effectiveness, making them indispensable in large-scale projects. For example, in residential construction, common nails are widely used for framing walls, securing subfloors, and assembling roof trusses. Their ability to handle high-stress applications without bending or breaking ensures their continued relevance in the construction-heavy states of Texas, California, and Florida, where housing developments and infrastructure projects are booming.

Another factor driving the dominance of common nails is their compatibility with pneumatic nail guns, which are widely used in the construction industry to improve efficiency. These nails are available in a variety of sizes and finishes, including galvanized options for outdoor use, making them suitable for diverse applications. Retailers also report strong demand for common nails among DIY enthusiasts, who use them for home improvement projects like building fences, furniture, or shelving. Their affordability and availability in both bulk contractor packs and smaller retail-friendly packaging ensure they remain a staple product across multiple market segments. This combination of versatility, affordability, and widespread availability solidifies the position of common nails as a leading product in the US carbon steel nail market.

By Nail Size: Medium Nails Generate More Than 41.65% Revenue

Medium-sized nails (1-2.5 inches or 25-64mm) generate over 41.65% of revenue in the US carbon steel nail market in 2024 due to their versatility and suitability for a wide range of applications. These nails are essential in framing, carpentry, and paneling, making them a preferred choice for contractors and builders. Medium nails are particularly effective for securing medium-density materials like plywood, softwoods, and drywall, ensuring a strong bond without splitting the substrate. For example, in Florida’s hurricane-prone regions, medium nails are heavily used in roofing and structural repairs, where precision and holding strength are critical to withstand extreme weather conditions. Their size makes them ideal for assembling wooden structures like cabinets, flooring systems, and wall studs, which are integral to both residential and commercial construction.

The demand for medium nails is also driven by their popularity among DIY consumers in the US carbon steel nail market, who use them for small-scale woodworking projects and home repairs. Manufacturers have optimized production to cater to this demand, offering medium nails in both bulk contractor packs and smaller retail-friendly packaging. Contractors often purchase these nails in large quantities for framing and paneling work, as they strike the perfect balance between size, strength, and versatility. Additionally, medium nails are compatible with pneumatic nail guns, which are widely used in the construction industry to improve efficiency and reduce labor time. This combination of professional and consumer demand explains why medium nails dominate revenue generation in the market.

By Application: Framing Applications Account for Over 28.52% of Revenue Share

Framing applications contribute over 28.52% of the US carbon steel nail market’s revenue in 2024, driven by the construction industry’s reliance on carbon steel nails for structural integrity. Framing forms the backbone of residential and commercial buildings, and carbon steel nails are essential for securing wood and other materials in place. These nails are particularly favored for their ability to provide strong, durable connections in load-bearing structures, such as walls, floors, and roof trusses. For example, in Texas and Florida, where residential construction remains a top priority, framing nails are in high demand for assembling wooden studs and beams in new housing developments. Their ability to maintain structural stability under stress and resist corrosion in treated lumber has made them indispensable in framing applications.

Another key driver of demand for framing nails is their compatibility with pneumatic nail guns, which are widely used in the construction sector. Contractors prefer carbon steel nails due to their affordability and availability in various finishes, such as galvanized coatings, which offer added durability in humid or coastal areas like Florida. Manufacturers have optimized nail designs for framing applications, offering ring-shank and spiral-shank variants that provide enhanced holding power in high-stress environments. The growing adoption of modular construction techniques, which rely heavily on pre-framed panels, has further boosted the consumption of framing nails. These nails are often supplied in bulk packaging to contractors, ensuring cost-effective and uninterrupted workflows. Together, these factors underline why framing applications continue to generate a significant share of revenue in the US carbon steel nail market.

By Packaging: Collated Packaging (Strips/Coils) Dominates the US Carbon Steel Nail Market with Over 49.10% Market Share

Collated packaging, including strips and coils, accounts for over 49.10% of the US carbon steel nail market in 2024 due to its efficiency and suitability for high-volume construction work. This packaging format is heavily favored by contractors and builders, as it allows for seamless use in pneumatic and electric nail guns. Collated nails are pre-arranged in strips or coils, enabling workers to load them quickly and fire them in rapid succession. This significantly reduces labor time and increases productivity, especially in large-scale projects like framing, roofing, and siding. In high-construction-demand states like California and Texas, where housing developments and infrastructure projects are booming, collated nails have become an essential tool for contractors aiming to meet tight deadlines.

Another key factor driving the demand for collated packaging is its convenience and safety. Collated nails reduce the risk of mishandling or misplacement on busy job sites, ensuring a smoother workflow. Coils, in particular, allow for a higher nail count per load, minimizing interruptions during work. This is especially beneficial in large-scale applications like subfloor installation, where thousands of nails are required. Manufacturers have also innovated within this segment, offering collated nails in weather-resistant finishes like galvanized or epoxy-coated variants for outdoor or high-moisture environments. Retailers report strong demand for collated nails among professional contractors, with bulk packaging formats being the most popular due to cost-efficiency. These factors collectively explain why collated packaging dominates the US carbon steel nail market, offering unmatched utility, productivity, and safety for end users.

Customize This Report + Validate with an Expert

Access only the sections you need—region-specific, company-level, or by use-case.

Includes a free consultation with a domain expert to help guide your decision.

To Understand More About this Research: Request A Free Sample

Top Players in the US Carbon Steel Nail Market

- Stanley Black & Decker, Inc.

- Mid Continent Steel & Wire "

- Simpson Strong-Tie Company, Inc.

- Grip-Rite

- Maze Nails

- National Nail Corp.

- Freeman Manufacturing & Supply Co.

- Specialty Nail Company

- Other Prominent Players

Market Segmentation Overview

By Nail Type

- Common Nails

- Box Nails

- Finishing Nails

- Brad Nails

- Duplex Nails

- Ring Shank Nails

- Masonry Nails

- Others

By Size

- Short Nails (Below 1 inch / 25mm)

- Medium Nails (1-2.5 inches / 25-64mm)

- Long Nails (2.5-4 inches / 64-102mm)

- Extra-Long Nails (Above 4 inches / 102mm)

By Packaging

- Bulk

- Bundled

- Collated (Strips/Coils)

By Application

- Framing

- Roofing

- Drywall Installation

- Flooring

- Pallet and Crate Assembly

- Fencing and Decking

- Others

By End User

- Construction

- Furniture and Woodworking

- Logistics and Packaging

- Manufacturing

By Distribution Channel

- Online

- Offline

- Direct Sales

- Distributors & Wholesalers

- Retail Stores

- Hardware Stores

- Home Improvement Chains

LOOKING FOR COMPREHENSIVE MARKET KNOWLEDGE? ENGAGE OUR EXPERT SPECIALISTS.

SPEAK TO AN ANALYST

.svg)