India Casting Polyurethane Market: By Product Type (Rolls, Formwork, Pads, Sheets, Others); Prepolymer Type (Polyester Base Prepolymer, Polyether Base Prepolymer, Polycaprolactone Base Prepolymer, Others); Resin Grade (Standard Grade, High-Performance Grade, Specialty Grade, Others); Manufacturing Process (Reaction Injection Molding (RIM), Casting (Liquid Polyurethane), Extrusion, Compression Molding, Others); Design (Rigid, Flexible, Foamed, Elastomeric, Others); Application (Industrial Castings, Wheels & Tires, Belt & Hoses, Medical Devices, Footwear Components, Concrete Blocks, Others); Distribution Channel (Direct Sales, Online Sales, Distributors/Wholesalers); Industry (Automotive, Mechanical, Electronics & Instruments, Aerospace & Defense, Footwear & Sports, Healthcare, Others); Region—Market Size, Industry Dynamics, Opportunity Analysis and Forecast for 2025–2033

- Last Updated: 29-Jul-2025 | | Report ID: AA07251421

Market Scenario

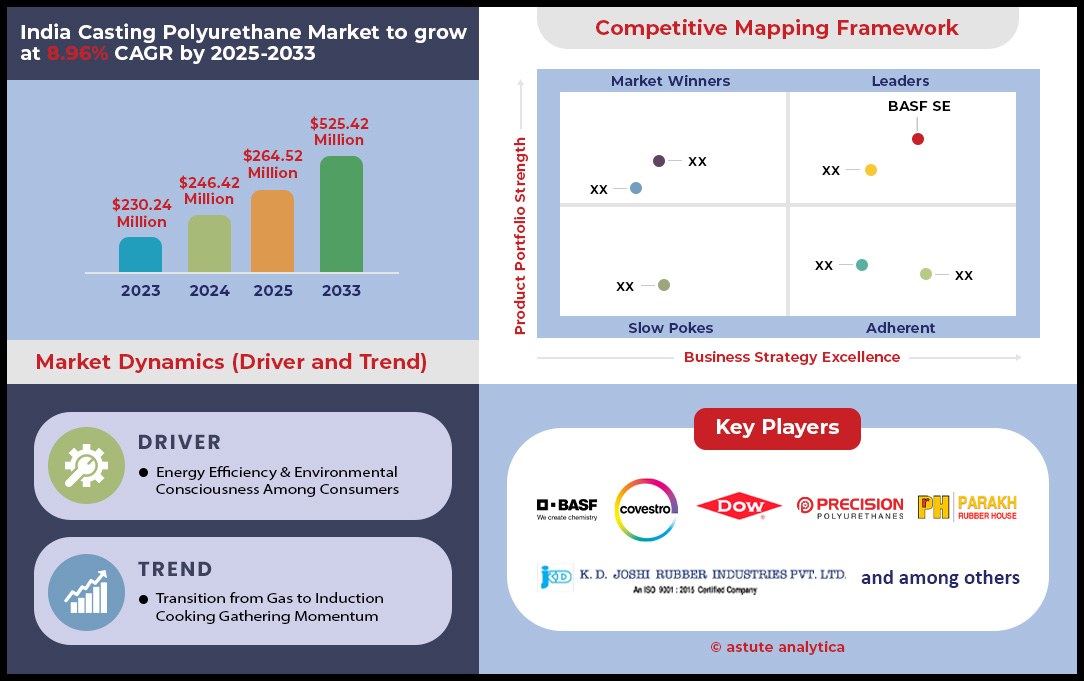

India casting polyurethane market was valued at US$ 246.42 million in 2024 and is projected to hit the market valuation of US$ 525.42 million by 2033 at a CAGR of 8.96% during the forecast period 2025–2033.

The India casting polyurethane market is on the cusp of a significant and sustained growth phase, propelled by powerful economic tailwinds and burgeoning industrial demand. This expansion is directly mirrored in key consuming sectors; the automotive industry, on track to produce over 30 million vehicles in 2024, and a construction sector bolstered by a 13% share of FDI inflows, are creating a foundational demand for high-performance cast polyurethane components. This confluence of macro-economic strength and sector-specific growth establishes a highly favorable environment for market participants.

Underpinning this demand in the casting polyurethane market is India's formidable industrial and manufacturing backbone. As the world's second-largest producer of castings with an annual output of 12 million tons, the nation's foundry sector, which is expected to grow by 7% in 2024, is a critical consumer. This robust domestic activity has not gone unnoticed, attracting significant strategic investment that signals deep market confidence. BASF's plan to increase production capacity by over 40% by 2025 and the inauguration of its new Polyurethane Technical Development Center in Mumbai in May 2024 are clear indicators of a market poised for innovation and volume growth. Similarly, the establishment of a new distribution center by Pearl Polyurethane Systems in late 2023 underscores the logistical scaling required to meet this rising demand.

Looking ahead, the India’s casting polyurethane market trajectory is further brightened by diversification into high-tech sectors and evolving trade dynamics. India's push towards a US$1 trillion digital economy by 2025 will unlock new applications in electronics, while the organized furniture market's projected growth by 2035 promises a new long-term revenue stream. While imports are forecast to reach 184.4 million kilograms by 2026 to satisfy immediate needs, domestic export capability is also on the rise, with projections of 27.7 million kilograms for the same year. This indicates a dynamic evolution from a consumption-led market to a more balanced ecosystem, solidifying the promising and multifaceted future of the India casting polyurethane market.

To Get more Insights, Request A Free Sample

Key Market Snapshot of the India Casting Polyurethane Market

- EV Sector Demands Sophistication: A notable trend in the automotive space is the lengthening of prototype development cycles for EV components from 18 to 28 months, signaling a shift toward more complex, high-value polyurethane applications that demand intensive R&D.

- MDI's Financial Dominance: In 2024, Methylene diphenyl di-isocyanate (MDI) solidified its position as the largest revenue-generating raw material, making its price stability and supply chain integrity the most critical financial factors for manufacturers in the India casting polyurethane market.

- Coimbatore: The Epicenter of Casting Demand: The city of Coimbatore represents a crucial geographic stronghold, accounting for nearly 40% of the country's entire casting output, making it the single most important regional market for casting polyurethane suppliers.

- A Vast and Distributed Customer Base: The sheer scale of the foundry industry, with over 4,500 individual foundries employing more than 500,000 people, illustrates the vast and decentralized nature of the customer base for casting polyurethane materials.

- Innovation Hub Signals Market Maturity: The launch of BASF's 2,000-square-meter Polyurethane Technical Development Center is a leading indicator that the market is maturing beyond commodity products and moving towards specialized, custom-formulated solutions.

- Foreign Trade Imbalance Highlights Opportunity: The significant gap between projected imports (184.4 million kg) and exports (27.7 million kg) by 2026 underscores a substantial domestic production deficit, representing a clear and immediate opportunity for local manufacturing expansion.

India's Industrial Engine Fueling Explosive Demand in the Casting Polyurethane Market

The industrial and manufacturing ecosystem in India serves as the primary engine for the nation's casting polyurethane market, creating a deep and continuously expanding reservoir of demand. The sheer scale of this consumption is anchored in the foundry sector, which, as of early 2024, is producing a massive 12 million tons of castings annually. This output is not static; the sector is projected to grow by a further 7% in 2024, directly translating to increased orders for durable polyurethane patterns and core boxes. This demand is serviced by a vast network of over 4,500 individual foundries, a sector that provides livelihoods for over 500,000 people.

Geographically, this activity is highly concentrated, with the city of Coimbatore alone accounting for a remarkable 40% of the country's total casting output. Parallel to this, the automotive industry is a colossal consumer, on track to produce over 30 million vehicles in 2024. As the auto components industry powers towards its goal of becoming the world's 3rd largest by 2025, the need for high-performance PU parts will only intensify, a trend underscored by the lengthening of EV component development cycles from 18 to 28 months, signaling a clear shift towards more complex applications within the India casting polyurethane market.

How Infrastructure and Construction Underpin Casting Polyurethane Growth?

India's ambitious infrastructure development agenda provides a foundational and non-cyclical demand stream that is critical for stakeholders in the India casting polyurethane market. The immense scale of this sector is demonstrated by its baseline economic contribution, which was recorded at US$31.53 billion in a single quarter (Q3 2021). This activity is significantly de-risked and accelerated by robust financial inflows, with infrastructure projects attracting a total of $81.72 billion in 2021. This capital is translating into a multitude of projects requiring durable and resilient components like concrete molds, pipe linings, and bridge bearings, for which casting polyurethane is the ideal material.

Looking towards future growth drivers, India’s strategic push to create a US$1 trillion digital economy by 2025 will necessitate the construction of data centers and advanced manufacturing plants, opening new avenues for PU applications. Furthermore, diversification is evident in the projected growth of the organized commercial furniture market by 2035, which will create a long-term, sustained demand for high-quality molded polyurethane components, adding another resilient layer of consumption.

Capital, Chemistry, and Control: Navigating the Supply Chain of India's Polyurethane Market

For stakeholders, navigating the strategic landscape of investment, innovation, and raw material flow is paramount to success in the India casting polyurethane market. Confidence in the market's future is unequivocally demonstrated by major capital investments, headlined by BASF India's plan to increase production capacity by over 40%, with the new output scheduled to come online in the second half of 2025. This commitment to growth is matched by a focus on innovation, evidenced by the May 2024 inauguration of a new 2,000-square-meter Polyurethane Technical Development Center in Mumbai. Logistical capabilities are also being scaled up, as shown by Pearl Polyurethane Systems' new distribution center in Maharashtra, established in December 2023.

The trade dynamics reveal a casting polyurethane market with voracious domestic demand; while exporters shipped 3,630 consignments between late 2023 and 2024 and are forecast to export 27.7 million kilograms by 2026, this is dwarfed by projected imports of 184.4 million kilograms for the same year. Critically, on the raw material front, while MDI was the largest revenue generator in 2024, stakeholders must brace for a tight supply of TDI throughout the year due to a major overseas plant shutdown, a factor that will significantly influence cost structures.

Segmental Analysis

By Product

The dominance of rolls as the leading product type within the casting polyurethane market in India by capturing over 30.60% market share is unequivocally driven by the nation's robust and expanding industrial backbone. These components are not merely products but essential cogs in the machinery of progress, particularly in heavy industries like steel, textiles, paper, and material handling. Polyurethane rollers are celebrated for their exceptional performance under duress, offering a superior alternative to traditional rubber and metal. Their ability to be custom-formulated is a key differentiator, allowing manufacturers to specify components that meet precise operational demands. For instance, in the demanding steel sector, polyurethane rollers with a hardness of 45-60 Shore A are increasingly adopted for their proven ability to extend roll life and drastically reduce replacement frequency.

- Exceptional load-bearing capacity, carrying up to four times more than rubber.

- Customization for specific industrial needs, such as the 45-60 Shore A hardness for steel.

- Growing automation in manufacturing that necessitates durable, high-precision roller solutions.

This demand permeates numerous sectors, creating a ripple effect across the India casting polyurethane market. The projected 7-8% growth of the Indian paper industry in 2025 is set to directly fuel the need for durable polyurethane rollers capable of withstanding modern, high-speed production lines. Similarly, the explosive growth of e-commerce has spurred a surge in demand for efficient conveyor and packaging systems, where polyurethane rollers are a critical component. Acknowledging these diverse needs, manufacturers are increasingly offering custom-formulated rollers for industries ranging from food processing to mining. This innovation extends to material science, with a clear market trend towards developing rollers with enhanced load-bearing capacity and superior abrasion resistance.

The Unwavering Reign of Elastomeric Design Within India's Polyurethane Sector

With nearly 36% market share, the prevalence of elastomeric design within the casting polyurethane market in India is a testament to its unparalleled versatility and performance. Polyurethane elastomers uniquely bridge the gap between the strength of rigid plastics and the flexibility of rubber, a hybrid quality that engineers leverage for high-impact, high-abrasion, and heavy-load applications. This adaptability makes it a superior replacement for conventional materials, driving its adoption across India’s key growth sectors. The market is experiencing a significant upswing, with elastomer production in India rising by 8% in 2024, spurred by exports and trends in the premium shoe market. This momentum is expected to continue, with projections of 8-9% annual growth by 2025, signaling a powerful market rebound. The financial scale of this dominance is substantial, evidenced by the Indian construction elastomers market alone generating a revenue of US$ 555.8 million in 2024, highlighting its critical role in the nation's infrastructure development in the casting polyurethane market.

- A unique combination of plastic's rigidity and rubber's flexibility.

- Projected annual growth of 8-9% by 2025, signaling a strong market rebound.

- The construction elastomers market alone generated US$ 555.8 million in revenue in 2024.

This growth is anchored in the country's thriving automotive and industrial sectors. The Indian automotive industry, which produced 2,358,041 vehicles in April 2024, is a major consumer of polyurethane elastomers for manufacturing durable, vibration-damping components. The competitive landscape, featuring key global players like BASF SE, Covestro AG, and Huntsman Corporation, indicates a mature and robust market.

Industrial Casting: The Powerhouse Application Driving the Market Forward

The heavy reliance on casting polyurethane for industrial applications is a cornerstone of the Indian casting polyurethane market, fueled by the material's exceptional durability, strength, and adaptability. It stands as a high-performance, cost-effective alternative to metal, plastic, and rubber, enabling the manufacture of complex, custom-shaped parts for a wide array of machinery and equipment. As a result, the segment is currently controlling more than 30.54% market share. This capability is perfectly aligned with the goals of the 'Make in India' initiative, which seeks to bolster domestic manufacturing. As industries strive for greater operational efficiency and reduced downtime, the demand for long-lasting components made from casting polyurethane intensifies. This market need was recognized with the inauguration of a 2,000 sq meter polyurethane technical development center in Mumbai in May 2024, a facility dedicated to supporting the market development of precisely these industrial applications and signaling strong future growth.

- The 'Make in India' initiative is a significant catalyst for domestic demand.

- A 2,000 sq meter technical development center was inaugurated in Mumbai in May 2024.

- Superior performance as a cost-effective replacement for metal, plastic, and rubber.

The application of industrial casting is diverse and expanding rapidly in the Indian casting polyurethane market. The oil and gas industry is increasingly using polyurethane for downhole tools and pipe protection due to its excellent wear resistance. On a global scale, the polyurethane rollers market, driven by industrial use, was valued at US$ 1.5 billion in 2023, with Asia-Pacific poised as the fastest-growing region. Innovation is also a key driver, with 3D printing of polyurethane gaining traction for creating high-quality prototypes and finished industrial goods. This trend is supported by the Indian government's push for 50 new 3D printing machines, which will boost the use of castable polyurethanes for rapid prototyping by 2025. This is further validated by a leading Indian foundry group's significant investment in 3D printing technology for creating patterns and molds. With India's steel demand projected to grow by 8.2% in 2024, the need for wear-resistant components in steel plants will rise in tandem, cementing industrial casting's role as the powerhouse application.

Customize This Report + Validate with an Expert

Access only the sections you need—region-specific, company-level, or by use-case.

Includes a free consultation with a domain expert to help guide your decision.

Why Polyester-Based Prepolymers Are the Undisputed Champions of the Indian Market

Polyester-based prepolymers with over 44.71% market share are the definitive leaders in the Indian casting polyurethane market, a position earned through an optimal blend of superior mechanical properties and economic viability. These prepolymers provide an exceptional balance of high tensile strength, tear resistance, and abrasion resistance, making them the material of choice for a vast spectrum of demanding applications. Their inherent toughness and durability are indispensable for manufacturing components subjected to harsh operational conditions, from industrial machinery to consumer goods. This is evident in the seals industry, where polyester grades of polyurethane are overwhelmingly preferred for their robust resistance to hydrocarbon oils and hydraulic fluids. The market's confidence is reflected in global trends, with projections indicating rapid growth for polyester base prepolymers through 2028. Supporting this, BASF's strategic expansion of its Shanghai plant to 18,800 metric tons per year in 2025 is designed to meet soaring demand across Asia, with India being a key target casting polyurethane market.

- Superior mechanical properties offering high tensile strength and abrasion resistance.

- Strong demand from the footwear sector, which holds a 23% market share by consumption.

- Excellent resistance to hydrocarbon oils and hydraulic fluids, making it ideal for seals.

The demand for these prepolymers is driven by a trifecta of India's most vital sectors: automotive, footwear, and industrial manufacturing. The footwear industry, a major consumer, already commanded a 23% share of Indian polyurethane consumption as of 2023-2024, using polyester-based polyurethane for durable, comfortable soles. In the automotive sector, these materials are crucial for vehicle lightweighting and improved fuel efficiency. The versatility of polyester-based formulations is expanding, with specialty grades being developed for high-temperature applications and polyurethane coatings based on these resins seeing double-digit growth in India in 2024.

To Understand More About this Research: Request A Free Sample

Top 10 developments Shaping the India Casting Polyurethane Market

- BASF's Major Capacity Expansion (2025): BASF India is significantly increasing its production capacity for key materials like Ultramid® (PA) and Ultradur® (PBT) by over 40% at its facilities in Panoli, Gujarat, and Thane, Maharashtra, with the new capacity slated to be available in the second half of 2025.

- BASF's New R&D Hub Launch (2024): In May 2024, BASF inaugurated a state-of-the-art Polyurethane Technical Development Center in Mumbai. This 2,000-square-meter facility is dedicated to fostering local innovation and developing custom polyurethane solutions.

- Pearl Polyurethane's Distribution Network Growth (2024): Following the opening of its Maharashtra distribution center in late 2023, Pearl Polyurethane Systems announced plans in 2024 to further expand its logistics and supply chain network across India to better serve regional demand.

- Knauf Insulation's Strategic Acquisition (2025): In a significant move impacting the broader industrial materials market, Knauf Insulation completed its acquisition of Indian company GlassTech Insul Pvt Ltd in May 2025, strengthening its manufacturing footprint in the region.

- Covestro's Focus on High-Tech Applications (2024): Covestro India has increased its focus on supplying specialty thermoplastic polyurethanes (TPU) for the rapidly growing electronics and EV charger manufacturing sectors throughout 2024, investing in application development.

- Manali Petrochemicals' System House Investment (2024): Manali Petrochemicals Ltd announced further investment into its Notedome-branded polyurethane systems house to enhance its capabilities in developing custom casting formulations for specialty industrial applications.

- Expanded Polytetramethylene Ether Glycol (PTMEG) Imports (2024): Throughout 2024, several Indian polyurethane system houses increased their import volumes of specialty PTMEG, a key raw material for high-performance cast elastomers, to meet rising demand from heavy engineering and automotive sectors.

- Roha Dyechem's New Plant (2025): While focused on colorants, Roha Dyechem is commissioning a new plant at Dahej, which will enhance its production of specialized pigments and dispersions for the plastics and polyurethane industries, with operations starting in 2025. Giving boost to the casting polyurethane market growth.

- Funding for Automotive Component Start-ups (2024): Several venture capital funds have shown increased interest in start-ups developing innovative automotive components using advanced materials like cast polyurethane, with multiple seed funding rounds announced in 2024.

- Government PLI Scheme Impact (2024-2025): The Production Linked Incentive (PLI) schemes for automotive, and electronics manufacturing have spurred domestic and international firms to increase investment in local component production, directly boosting demand for casting polyurethane.

Top Companies in the India Casting Polyurethane Market

- BASF SE

- Covestro AG

- DOW Inc.

- Rubber Regenerating & Processing Co

- Precision Polyurethanes

- K.D. Joshi Rubber Industries Pvt. Ltd .

- Perfect Polymers

- Parakh Rubber House

- D.P. Rubber Pvt. Ltd.

- Suryakiran Industries

- SOFTEX INDUSTRIAL PRODUCTS PVT. LTD .

- Other Prominent Players

Market Segmentation Overview

By Product Type

- Rolls

- Formwork

- Pads

- Sheets

- Others

By Prepolymer Type

- Polyester Base Prepolymer

- Polyether Base Prepolymer

- Polycaprolactone Base Prepolymer

- Others

By Resin Grade

- Standard Grade

- High-Performance Grade

- Specialty Grade

- Others

By Manufacturing Process

- Reaction Injection Molding (RIM)

- Casting (Liquid Polyurethane)

- Extrusion

- Compression Molding

- Others

By Design

- Rigid

- Flexible

- Foamed

- Elastomeric

- Others

By Application

- Industrial Castings

- Wheels & Tires

- Belt & Hoses

- Medical Devices

- Footwear Components

- Concrete Blocks

- Others

By Distribution Channel

- Direct Sales

- Online Sales

- Distributors/Wholesalers

By Industry

- Automotive

- Mechanical

- Electronics & Instruments

- Aerospace & Defense

- Footwear & Sports

- Healthcare

- Others

LOOKING FOR COMPREHENSIVE MARKET KNOWLEDGE? ENGAGE OUR EXPERT SPECIALISTS.

SPEAK TO AN ANALYST

.svg)