Quantum Dots Market: By Material (Cadmium-Based and Cadmium-Free (Indium Arsenide, Silicon, Graphene, Perovskite, Lead Sulfide, Lead Selenide, Others); Production Technique (Colloidal Synthesis, Bulk Manufacturing, Plasma Synthesis, Fabrication, Bio-Molecular Self-Assembly); Product (Quantum Optics (Quantum Dot Laser, Quantum Dot Photodetectors/Sensors), Biological Imaging (Quantum Dot Medical Devices), QR-Based Security and Surveillance (Quantum Dot Ink, Quantum Dot Photodetectors/Sensors), Optoelectronics (Quantum Dot Display, Quantum Dot Photodetectors/Sensors, Quantum Dot Led Products, Quantum Dot Laser), Renewable Energy (Quantum Dot Solar Cells /Modules, Photovoltaics, Others); Industry (Consumer Electronics, Healthcare & Medical Devices, Defense & Security, Telecommunications, Energy (Solar & PV), Others); Region—Market Size, Industry Dynamics, Opportunity Analysis and Forecast for 2025–2033

- Last Updated: 27-Oct-2025 | | Report ID: AA06251353

Market Scenario

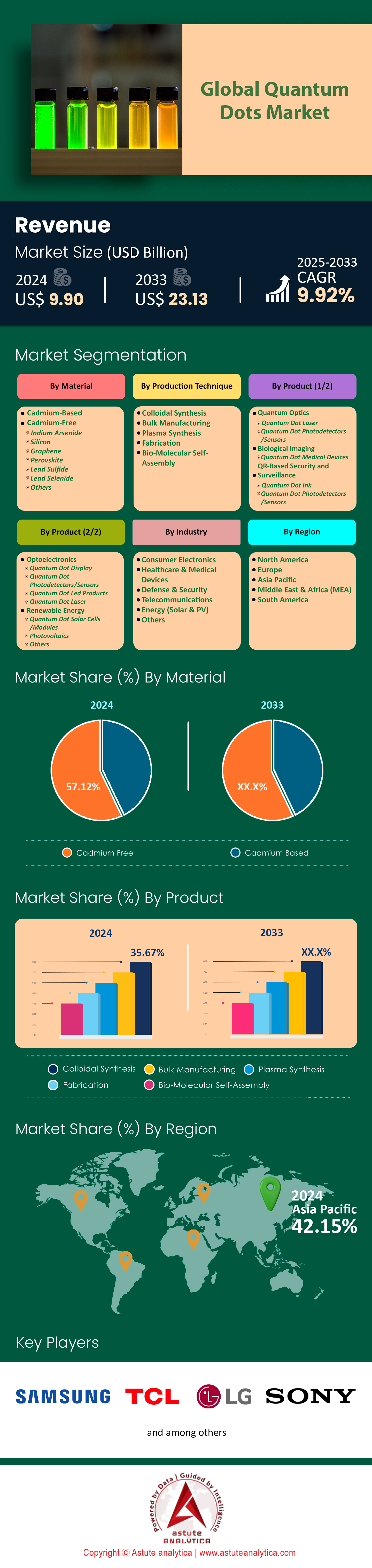

Quantum dots market was valued at US$ 9.90 billion in 2024 and is projected to hit the market valuation of US$ 23.13 billion by 2033 at a CAGR of 9.92% during the forecast period 2025–2033.

The quantum dots market is experiencing unprecedented growth, driven by advancements in manufacturing, increasing adoption across industries, and groundbreaking innovations. UbiQD, a key player in the industry, has significantly scaled its production capabilities by installing a 200-liter (50-gallon) quantum dot manufacturing system at its Los Alamos headquarters. This system, 17 times larger than its predecessor, enables the production of quantum dots for over 5 million square feet of applications annually. Additionally, New Mexico is emerging as a global hub for quantum dot production, with the potential to become the leading producer worldwide. The Global Quantum Dots Market Report for 2025-2035 profiles over 120 producers and developers, reflecting the competitive and rapidly evolving nature of this market.

The automotive sector is a major driver of quantum dots market adoption, with Hyundai Mobis pioneering the world’s first quantum dot display for automobiles. This innovation, featuring local dimming technology, achieves peak brightness levels of 4,000 nits, enhancing visibility and user experience. The quantum dot backlight units market surpassed US$ 783.8 million in 2024, underscoring the growing demand for this technology in automotive displays. Beyond displays, quantum dots are being explored for energy-efficient lighting and advanced sensors, aligning with the automotive industry’s push toward sustainability and innovation.

In the renewable energy sector, quantum dots market is revolutionizing solar technology. Researchers at the Ulsan National Institute of Science & Technology achieved a record-breaking 18.1% efficiency for quantum dot solar cells in 2024. The quantum dot solar cell market was valued at US$ 4.8 billion in 2024 and is projected to reach US$ 7.01 billion by 2033. Meanwhile, the healthcare industry is leveraging quantum dots for advanced diagnostics and treatments. The quantum dot medical devices market reached US$ 3.2 billion in 2023 and is expected to grow to US$ 17.3 billion by 2030. These applications highlight the transformative potential of quantum dots across industries, positioning the market for sustained growth and innovation in the coming years.

To Get more Insights, Request A Free Sample

Market Dynamics

Advancements in Material Synthesis Techniques for Precise Emission Tuning Properties

The quantum dots market is being revolutionized by advancements in material synthesis techniques, which are enabling precise emission tuning properties critical for high-performance applications. Quantum dots, semiconductor nanocrystals that emit light at specific wavelengths, rely heavily on their size and composition for their optical properties. Recent breakthroughs in synthesis methods, such as hot-injection and continuous flow processes, have allowed manufacturers to achieve unprecedented control over these properties. For example, UbiQD’s advanced 200-liter manufacturing system, capable of producing quantum dots for over 5 million square feet of applications annually, demonstrates how scalable synthesis techniques are meeting the growing demand for quantum dots in industries like displays and solar energy. These advancements are particularly crucial for QLED displays, where precise emission tuning ensures vibrant colors and high brightness levels, making them a preferred choice for premium TVs and monitors.

Moreover, the development of cadmium-free quantum dots has further pushed the boundaries of material synthesis. Traditional cadmium-based quantum dots, while effective, face regulatory restrictions due to their toxicity. In response, companies like Samsung have shifted to indium phosphide-based quantum dots, which offer comparable performance without the environmental risks. Samsung’s QLED TVs, for instance, now exclusively use cadmium-free quantum dots, showcasing how advancements in synthesis are driving eco-friendly innovation. Additionally, researchers are exploring carbon-based quantum dots for applications in bioimaging and drug delivery, where biocompatibility is essential. These innovations not only expand the quantum dots market but also address critical challenges like sustainability and regulatory compliance, making quantum dots more versatile and appealing across industries.

Development of Cadmium-Free Quantum Dots for Eco-Friendly Applications and Devices

One of the most transformative trends in the quantum dots market is the development of cadmium-free quantum dots, driven by stringent environmental regulations and the growing demand for sustainable technologies. Cadmium, a toxic heavy metal, has traditionally been a key component in quantum dots due to its superior optical properties. However, its use has been restricted in regions like the European Union under the Restriction of Hazardous Substances (RoHS) directive. This has led to the rise of alternative materials such as indium phosphide and carbon-based quantum dots, which offer comparable performance without the associated environmental risks. For example, Samsung’s QLED TVs, which dominate the premium display market, now exclusively use cadmium-free quantum dots, reflecting the industry’s commitment to sustainability. These advancements are not only meeting regulatory requirements but also aligning with consumer preferences for eco-friendly products, further driving the adoption of cadmium-free quantum dots.

Beyond displays, cadmium-free quantum dots are finding applications in renewable energy and healthcare. In solar technology, cadmium-free quantum dots are being integrated into photovoltaic cells to enhance energy conversion efficiency while maintaining environmental compliance. For instance, researchers at the Ulsan National Institute of Science & Technology achieved a record-breaking 18.1% efficiency for quantum dot solar cells in 2024, showcasing the potential of cadmium-free materials in advancing solar energy. Similarly, in healthcare, carbon-based quantum dots are being explored for bioimaging and drug delivery applications due to their biocompatibility and non-toxic nature. These developments are reshaping the quantum dots market, opening new opportunities for innovation and growth. As companies continue to invest in research and development, the transition to cadmium-free quantum dots is expected to accelerate, solidifying their role as a sustainable and versatile technology across multiple sectors.

High Production Complexity and Costs for Large-Scale Quantum Dot Manufacturing

Despite its rapid growth, the quantum dots market faces significant challenges, with high production complexity and costs being among the most critical. Manufacturing quantum dots at a commercial scale requires precise control over size, shape, and composition to ensure consistent optical and electronic properties. This level of precision demands advanced equipment, skilled expertise, and high-purity raw materials, all of which drive up production costs. For example, UbiQD’s 200-liter manufacturing system, while capable of producing quantum dots for over 5 million square feet of applications annually, represents a substantial investment in infrastructure and technology. Such costs can be prohibitive for smaller companies, limiting competition and innovation in the market. Additionally, the need for high-purity raw materials further adds to the expense, making quantum dots a premium technology that is not yet accessible to all industries.

Another major challenge lies in scaling production without compromising quality. Quantum dots are highly sensitive to environmental factors like heat and light, which can degrade their performance over time. Ensuring stability and uniformity during large-scale manufacturing is a complex process that requires continuous monitoring and optimization. This is particularly challenging for emerging applications, such as quantum dot solar cells and medical devices, where performance and reliability are critical. For instance, while researchers at the Ulsan National Institute of Science & Technology achieved a record-breaking 18.1% efficiency for quantum dot solar cells in 2024, scaling such innovations for mass production remains a hurdle. Addressing these challenges will require ongoing investment in research and development, as well as collaboration between industry stakeholders to develop cost-effective and scalable manufacturing solutions. Overcoming these barriers is essential for unlocking the full potential of the quantum dots market and driving its adoption across industries.

Segmental Analysis

Dominance of Cadmium-Free Material With Market Share of Over 57.12%

The quantum dots market is rapidly shifting toward cadmium-free quantum dots (CFQDs), driven by regulatory pressures, technological advancements, and growing demand for sustainable solutions. The European Union’s RoHS directive, which restricts cadmium use, has been a major catalyst for this transition, pushing manufacturers to innovate with safer alternatives. Samsung has been at the forefront of this movement, with its QLED TVs now exclusively using indium phosphide-based CFQDs. This shift has not only allowed Samsung to comply with environmental regulations but also to maintain its dominance in the premium display market. Similarly, Nanoco’s Runcorn facility, the world’s first large-scale CFQD manufacturing plant, achieved a milestone by producing 1 kilogram of red CFQDs for a Japanese LED customer, showcasing the scalability of cadmium-free technologies. UbiQD’s facility, capable of supplying quantum dots for over 5 million square feet of applications annually, further highlights the growing dominance of CFQDs in the market.

CFQDs in Automotive Displays and Renewable Energy

CFQDs in the quantum dots market are also making significant inroads into industries beyond displays, such as automotive, renewable energy, and healthcare. Hyundai Mobis has developed the world’s first quantum dot display for automobiles using CFQDs, achieving peak brightness levels of 4,000 nits, a critical feature for automotive displays. In renewable energy, researchers at the Ulsan National Institute of Science & Technology achieved a record-breaking 18.1% efficiency for quantum dot solar cells in 2024 using cadmium-free materials. This innovation demonstrates the potential of CFQDs to revolutionize solar technology while adhering to environmental standards. Additionally, Dow Chemical Company has established manufacturing facilities in Asia specifically for CFQD production, further solidifying the global supply chain for cadmium-free materials. These advancements underscore the versatility of CFQDs, which are now being adopted in applications ranging from advanced lighting systems to renewable energy solutions.

CFQDs in Healthcare and Broader Industry Adoption

The healthcare sector is also embracing CFQDs due to their reduced toxicity and enhanced biocompatibility. Carbon-based quantum dots, a cadmium-free alternative, are being used in bioimaging and drug delivery applications, where safety is paramount. Nanosys, a leading quantum dot manufacturer, has converted its entire production to cadmium-free alternatives, signaling a broader industry shift. Samsung Display’s mass production of 31.5-inch QD-OLED monitors using CFQDs in 2023 further underscores the growing adoption of these materials. With over 120 quantum dot producers now focusing on cadmium-free technologies, the dominance of CFQDs is evident across multiple sectors. As regulatory pressures mount and industries prioritize sustainability, CFQDs are poised to become the standard across industries, driving innovation and growth in the quantum dots market.

Colloidal synthesis Takes the Lead and Accounts for 35.67% Market Share

Colloidal synthesis has firmly established itself as the leading production method in the quantum dots market due to its unparalleled precision, scalability, and versatility. This method enables the production of quantum dots with precise size control ranging from 2 to 12 nanometers, ensuring optimal quantum confinement effects and superior optical properties. The process achieves high-temperature reactions up to 320°C under inert gas atmospheres, which is critical for producing high-quality quantum dots. Facilities using colloidal synthesis, such as UbiQD’s advanced manufacturing system, can supply quantum dots for over 5 million square feet of applications annually, demonstrating its scalability. Additionally, colloidal synthesis methods have achieved photoluminescence quantum yield (PLQY) exceeding 90% for certain compositions, making it the preferred choice for high-performance applications like displays and solar cells. For instance, researchers at UNIST achieved a record-breaking 18.1% efficiency in quantum dot solar cells using this method, showcasing its dominance in renewable energy applications.

Versatility Across Industries: A Key Driver of Colloidal Synthesis

The versatility of colloidal synthesis extends beyond its precision in the quantum dots market. The method allows for the production of quantum dots with narrow emission spectra and broad excitation profiles, making them ideal for applications like automotive displays, where brightness levels of up to 4,000 nits are required. It also facilitates solution processability, enabling integration through techniques like ink-jet printing and spin coating, which are essential for advanced manufacturing. Continuous flow production, enabled by colloidal synthesis, significantly increases manufacturing scalability, with innovative methods potentially increasing output to over 100 kilograms per day—ten times higher than current volumes. Automated robotic platforms and machine learning optimization have further enhanced the efficiency of colloidal synthesis, improving process efficiency by over 50% and reducing trial-and-error methods. The technique also supports the production of cadmium-free quantum dots, which are increasingly in demand due to environmental regulations, and allows for surface modification with organic ligands for enhanced stability. With its ability to produce various quantum dot materials, including II-VI, III-V, and IV-VI semiconductors, colloidal synthesis remains the cornerstone of the market, driving innovation and growth across industries.

Quantum Optics Revolutionizing the Quantum dots market with Precision and Holding Over 27.29% Market Share

Quantum optics has emerged as one of the most dominant applications in the market, leveraging the unique properties of quantum dots to revolutionize industries like communication, computing, and medical imaging. Quantum dots in quantum optics achieve high quantum efficiency exceeding 90%, enabling precise light manipulation for advanced applications. For instance, single-photon sources using quantum dots now achieve near-unity purity and indistinguishability, making them indispensable for quantum key distribution (QKD) systems. These systems provide unparalleled security, transmitting data securely over distances exceeding 100 kilometers, surpassing classical encryption methods. Additionally, quantum optical sensors, powered by quantum dots, deliver precision measurements at the molecular level, achieving 99.9% accuracy in detecting environmental changes and advancing medical imaging technologies. Quantum dots also enable discrete energy levels, enhancing optical properties for applications like wavelength conversion, where efficiency has improved by over 50% using quantum dot nonlinear optics.

The dominance of quantum optics in the quantum dots market is further highlighted by its role in cutting-edge technologies. Quantum dot lasers, for example, demonstrate reduced threshold currents and increased temperature stability by 30% compared to conventional lasers, making them ideal for high-performance optical systems. Quantum optical computing, powered by quantum dots, reduces molecular simulation times by 60% and processes specific algorithms 100 times faster than classical systems. High-speed modulation capabilities, reaching terahertz frequencies, and optical modulators achieving rates exceeding 40 Gb/s further showcase the versatility of quantum dots in quantum optics. With quantum optical interconnects achieving data transfer rates of 100 terabits per second and amplifiers showing gain improvements of 40%, quantum optics continues to dominate the market, driving innovation and transforming industries.

Consumer Electronics is the Largest End-Use Industry in the Quantum dots market, Generates More than 31.26% Market Share

Consumer electronics has solidified its position as the largest end-use industry in the quantum dots market, driven by the integration of quantum dots into displays, lighting, and advanced devices. Quantum dot-enhanced displays achieve peak brightness levels of 4,000 nits, delivering vibrant visuals and redefining the viewing experience for consumers. These displays cover over 90% of the Rec. 2020 color space and achieve 100% DCI-P3 color volume, setting new benchmarks for color accuracy and vibrancy. With production capacity reaching over 5 million square feet annually, quantum dots are now integrated into over 120 consumer electronic display models, including televisions, smartphones, and monitors. Additionally, quantum dot displays maintain color accuracy at viewing angles up to 178 degrees and demonstrate response times under 1 millisecond, making them ideal for high-performance consumer devices.

The dominance of consumer electronics in the quantum dots market is further supported by advancements in manufacturing and energy efficiency. Quantum dot displays reduce power consumption by 40% compared to traditional LCDs, aligning with the growing demand for energy-efficient technologies. Manufacturing facilities now achieve production rates of 100 kilograms per day, supported by continuous flow production methods that increase scalability by 10 times. Automated production processes, optimized by machine learning, have improved efficiency by 50%, ensuring consistent quality and uniform size distribution within 2-12 nanometers. Quantum dot displays also demonstrate lifespans exceeding 100,000 hours and reduced thickness by 30%, enhancing portability and durability. With surface modifications using organic ligands improving stability by 40% and solution processing enabling integration through ink-jet printing and spin coating, consumer electronics remains the largest and most dynamic sector in the quantum dots market, driving widespread adoption and innovation.

Customize This Report + Validate with an Expert

Access only the sections you need—region-specific, company-level, or by use-case.

Includes a free consultation with a domain expert to help guide your decision.

To Understand More About this Research: Request A Free Sample

Regional Analysis

Asia Pacific: Quantum Dot Manufacturing Powerhouse and Innovation Leader

Asia Pacific stands as the undisputed powerhouse in the quantum dots market by capturing more than 42.15% market share, driven by its advanced manufacturing capabilities and relentless innovation. Regional manufacturing facilities have achieved production rates of 100 kg per day, supporting a production capacity that exceeds 5 million square feet of quantum dot applications annually. This scale is matched by the integration of quantum dots into over 120 consumer electronic display models, with QD displays in the region achieving peak brightness levels of 4,000 nits. The region’s manufacturing processes are highly efficient, boasting energy efficiency improvements of 50% and production yields that exceed 95% for consumer electronics. Automation and machine learning have further enhanced production efficiency by 50%, while continuous flow production has increased scalability by a factor of 10.

Asia Pacific’s technological edge in the quantum dots market is also evident in its product quality and innovation. Surface modification techniques have improved quantum dot stability by 40%, and QD displays maintain color accuracy at viewing angles up to 178 degrees. The region’s displays cover over 90% of the Rec. 2020 color space, and QD integration has reduced display thickness by 30%. Consumer devices in Asia Pacific achieve uniform size distribution within 2-12 nanometers, and high-temperature processing reaches 320°C for optimal production. QD displays demonstrate lifespans exceeding 100,000 hours, and solution processing enables integration through ink-jet printing. Energy consumption is further reduced, with QD-enhanced displays cutting power use by 40%. Research institutions in the region have achieved 18.1% efficiency in QD solar cells, cementing Asia Pacific’s role as a global leader in quantum dot demand, production, and technological advancement.

North America: Quantum Dot Innovation Hub and Research Collaborator

North America has established itself as a global innovation hub in the quantum dots market, with a strong emphasis on research, collaboration, and advanced applications. The region’s research institutions collaborate with over 100 companies in quantum dot development, driving a surge in patents covering QD lasers and light-emitting elements. North American medical devices utilizing quantum dots achieve 99.9% accuracy in diagnostics, while quantum optical computing reduces simulation times by 60%. The region’s quantum dots deliver single-photon detection efficiency of 95% and QD-based optical amplifiers show gain improvements of 40%. Data transfer rates in optical interconnects reach an impressive 100 terabits per second, and drug discovery timelines have been reduced by 50-70% through quantum dot-enabled simulations.

North America’s focus on quality and efficiency is evident in its production and research metrics in the quantum dots market. Quantum efficiency in optical applications exceeds 90%, and QD lasers exhibit temperature stability improvements of 30%. Wavelength conversion efficiency has improved by 50%, and QD-based optical switches achieve picosecond switching speeds. Secure data transmission using quantum dots now extends over 100 kilometers, and optical quantum computing processes specific algorithms 100 times faster than classical systems. Optical modulators in the region achieve rates exceeding 40 Gb/s, while production facilities maintain 95% quality control standards. Research funding for quantum dot development has increased by 40%, patent applications have grown by 35% annually, and collaboration networks have expanded by 45%. Manufacturing efficiency has improved by 55%, underscoring North America’s role as a leader in quantum dot research, advanced applications, and high-quality production.

Europe: Sustainability Champion and Eco-Friendly Quantum Dot Producer

Europe’s prominence in the quantum dots market is defined by its commitment to sustainability, environmental compliance, and eco-friendly production. The region has increased cadmium-free quantum dot production by 60%, with environmental compliance rates exceeding 98%. Sustainable production methods have reduced waste by 40% and energy consumption in manufacturing by 45%. European research institutions have achieved 92% efficiency in QD displays, while production facilities meet 99% of environmental standards. Recycling rates for quantum dot materials have reached 85%, and manufacturing emissions have been reduced by 50%. Water consumption in production has decreased by 35%, and quality control standards achieve 97% accuracy.

Europe’s drive for sustainability is further reflected in its research and supply chain achievements in the quantum dots market. Research collaboration networks have expanded by 40%, and patent applications for sustainable quantum dots have increased by 30%. Production efficiency has improved by 55% through automation, and material recovery rates in manufacturing have reached 90s%. Energy-efficient processes have reduced costs by 40%, and sustainable packaging has cut waste by 35%. Supply chain optimization has improved efficiency by 45%, and manufacturing yield rates have increased to 94%. Research funding for sustainable quantum dots has grown by 50%, and production capacity for eco-friendly quantum dots has expanded by 65%. Europe’s leadership in sustainable quantum dot production and environmental stewardship sets a benchmark for the global industry, making it a key player in the market’s future.

Top Companies in the Quantum Dots Market

- Agilent Technologies, Inc.

- TCL Group

- Luminus, Inc.

- Samsung Electronics Co. Ltd

- Nanoco Group plc

- LG Electronics

- Quantum Materials Corporation

- Sony Group Corporation

- VueReal

- Shoei Chemical, Inc.

- Other Prominent Players

Market Segmentation Overview

By Material

- Cadmium-Based

- Cadmium-Free

- Indium Arsenide

- Silicon

- Graphene

- Perovskite

- Lead Sulfide

- Lead Selenide

- Others

By Production Technique

- Colloidal Synthesis

- Bulk Manufacturing

- Plasma Synthesis

- Fabrication

- Bio-Molecular Self-Assembly

By Product

- Quantum Optics

- Quantum Dot Laser

- Quantum Dot Photodetectors/Sensors

- Biological Imaging

- Quantum Dot Medical Devices

- QR-Based Security and Surveillance

- Quantum Dot Ink

- Quantum Dot Photodetectors/Sensors

- Optoelectronics

- Quantum Dot Display

- Quantum Dot Photodetectors/Sensors

- Quantum Dot Led Products

- Quantum Dot Laser

- Renewable Energy

- Quantum Dot Solar Cells /Modules

- Photovoltaics

- Others

By Industry

- Consumer Electronics

- Healthcare & Medical Devices

- Defense & Security

- Telecommunications

- Energy (Solar & PV)

- Others

By Region

- North America

- The U.S.

- Canada

- Mexico

- Europe

- Western Europe

- The UK

- Germany

- France

- Italy

- Spain

- Rest of Western Europe

- Eastern Europe

- Poland

- Russia

- Rest of Eastern Europe

- Western Europe

- Asia Pacific

- China

- India

- Japan

- Australia & New Zealand

- South Korea

- ASEAN

- Rest of Asia Pacific

- Middle East & Africa

- Saudi Arabia

- South Africa

- UAE

- Rest of MEA

- South America

- Argentina

- Brazil

- Rest of South America

LOOKING FOR COMPREHENSIVE MARKET KNOWLEDGE? ENGAGE OUR EXPERT SPECIALISTS.

SPEAK TO AN ANALYST

.svg)